Developed by and for mining companies

The Metcelerate methodology was developed with employers to meet 21st Century workplace requirements.

“It works in practice” – is what the Metcelerate learners say.

Metcelerate provides learners with a skillset that would otherwise take years and high opportunity costs to achieve.

8 courses in total

The program

3 to 5 hours per week

Weekly dedication

16 to 18 months

Total length

+130 enrolled

Total participants

300 hours in total

Study load

+30 sites globally

Mining companies participating

The program consists of:

8 courses in total

The program

3 to 5 hours per week

Weekly dedication

16 to 18 months

Total length

+100 enrolled

Total participants

300 hours

Study load

+30 sites globally

Mining companies participating

What is covered in each course?

In this course you will see:

- Annual report

- Sustainability Report

- Cash flow analysis

In this course you will see:

- Problem identification and definition

- Execution of technical research

- Planning and managing technical research

- Communication and implementation

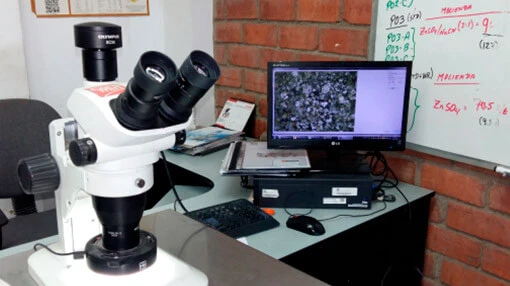

In this course you will see:

- Key minerals

- Mineralogical tools

- Process evaluation

- Texture impact

- Copper mass balance

In this course you will see:

- Crushing and screening

- Characterization and geometallurgy

- Modeling and simulation

- Grinding circuits

- Plant sampling and mass balance

- Operational performance evaluation

In this course you will see:

- What is flotation?

- Circuit configuration

- Inspection and maintenance

- Plant sampling

- Flotation chemistry

- Modeling and simulation

- Process optimization

- Advanced control

In this course you will see:

- Data uncertainty and error propagation

- Model developing with regression analysis

- Design, execution, and analysis of on-site trials

- Comparative statistics and hypothesis testing

- Experimental design

- How to choose a statistical method

In this course you will see:

-

Basics of sedimentation

-

Basic concepts of filtration

-

Thickeners in practice

-

Operational aspects in filtering

In this course you will see:

- Past, present and future

- Fundamentals of particle separation

- Magnetic concentration

- Sensor-based separation

- Basic mechanisms

- Gravity concentration

- Electrical separation

- Advanced control

In this course you will see:

- Fundamentals of Hydrometallurgy

- Copper Leaching

- Bauxite Processing

- Gold Cyanidation

- Cobalt Recovery

- Other commodities

Certificates for all courses

At the end of each course of the program, the participant receives a digital certificate that confirms the course was taken and another certificate upon completion of the program.

The four main features of the program

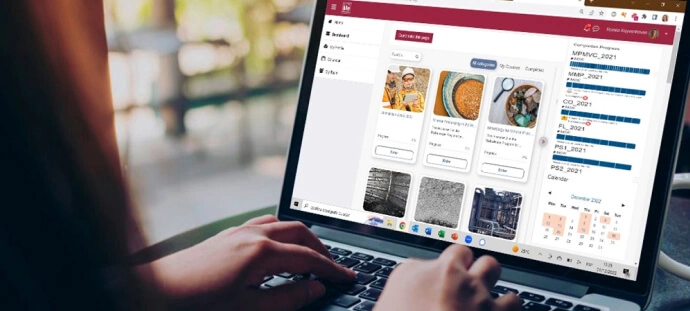

The self-guided study material is available through the unique Metcelerate on-line learning platform. The participants review the weekly study material at the most appropriate time during their work week, in order to be well prepared for the real-time (1-hour) tutorials. Access to the online material is through a highly reliable, secure, and proven platform, developed for Metcelerate, called the LMS (Learning Management System).

Each course includes a weekly live tutorial held by the course instructor in which participants are able to discuss the material and apply it to actual operational challenges that participants might be facing. The tutorials are also a great opportunity to clarify any doubts and interact with other participants. The sessions are recorded and are available for later review on the platform.

The periodic assignments are integral part of the program where the participants will have to apply the newly acquired knowledge and skills to an operational problem that requires an immediate solution.

The optimization project will be defined in coordination with the leaders of each participant’s operation. The topic to be addressed must be a complex and open problem that requires the acquisition, analysis, and interpretation of results and provides an opportunity for creativity in proposing solutions. Successful completion of this project means that you will have demonstrated the ability to formulate a problem in engineering terms, manage a schedule and resources, and find solutions by applying current and appropriate mineral processing tools and methods.

World-renowned experts

The Metcelerate program developers and course instructors are professionals with a unique backgrounds in applied research, operations, and professional training & human capital development, in each of the technical focus areas of the program.

The contents of the Metcelerate program are based on the essential functions that are required for plant operation:

Metallurgical process management:

Operational stability; automation, diagnostic tools; modeling and plant optimization.

Management of process input data:

Ore characterization; interaction of unit processes with upstream or downstream processes; design constraints vs. ore constraints.

Management of equipment performance data:

Sensor calibration; sampler availability and status; online measurement systems; quality control; preventive maintenance; site and laboratory QA/QC.

Calendar of the program in English

- Orientation week

- Mining value chain

- Process mineralogy

- Flotation

- Comminution

- S/L and S/S separation

- Hydrometallurgy

- Experimental design

- Optimization project

Mining value chain

Process mineralogy

Flotation

Comminution

S/L and S/S separation

Hydrometallurgy

Comminution

S/L and S/S separation

- Note: Move the cursor over the different bars to reveal their respective course name.

What's in the news

Learn how Metcelerate is leading the way in workplace-based skills development for the mining industry.